Wirral Fire Protection has just completed a major project with The Knowsley Large Business of the Year.

Conventional Smoke Detection Ruled Out

Our client Colloids scooped the award at The Knowsley Business Awards in November. The firm is a manufacturer of master batch – batches of coloured pellets used to tint plastics. As well as their plant on Merseyside they also have a production facility in China.

Due to its continued growth, the manufacturer has constructed a new warehouse and logistics facility. The height of the new warehouse ruled out conventional smoke detectors, metal detectors and the storage facilities ruled out the use of beam detectors. The masterbatch manufacturer required a dynamic fire safety solution and called upon Wirral Fire for a sound approach.

Dave Gell, our director, had already overseen the installation of a site-wide networked fire alarm system during 2017. And with a track record of providing fire safety to the firm, he set about finding a solution to protect the new warehouse.

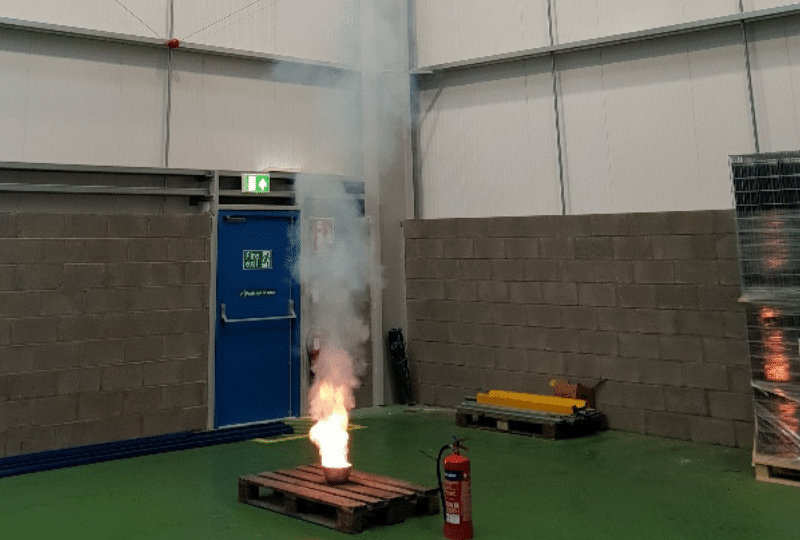

Air Sampling Solution

An aspiration system, that samples the air to detect changes that indicate there is a fire was a great solution for the 2,600sq ft facility. In layman’s terms the system resembles lengths of pipes that are perforated to allow for the air in the warehouse to be regularly checked. If there is a change in the air, indicating a fire has broken out, the system will trigger the fire alarm system.

Mike Sullivan who is the Health, Safety & Environmental Officer at the site says:

“The new system provides automatic fire protection in a challenging scenario. Dave and the team completed the work on time, to budget and were able to adhere to our stringent health and safety precautions. Wirral Fire Protection has been a trusted supplier to us for many years.”

Challenges of Access

Alongside the new warehouse Colloids have installed new logistics facilities, state-of-the-art production machinery and systems, plus new R&D laboratory equipment. Dave Gell explains the challenges of the major installation:

Alongside the new warehouse Colloids have installed new logistics facilities, state-of-the-art production machinery and systems, plus new R&D laboratory equipment. Dave Gell explains the challenges of the major installation:

“We always set out a schedule of work that minimises disruption to the business. The warehouse is more than 10m high and spans 2,600 sq ft so the scale of the job was significant. We completed the installation within two weeks despite having to manoeuvre access equipment around a huge racking system.”

The Wirral Fire Protection team is IPAF trained. This means we are holders of licenses issued by The International Powered Access Federation. Ensuring we keep our qualifications and expertise up to date provides peace of mind for our customers who want to take effective measures to preserve life and their businesses.